The Automatic Sand Blasting Machine has two stepper motor first motor is utilized for rotating the table and the second motor has utilized for moving up and down the gun by reciprocating movement. In the Automatic Sand Blasting Machines, the workpiece is put on the turntable and rotating through the stepper motor first and through the second motor, we can change the Sand Blasting nozzles position up and down, on the control panel have four switches. through switches, we can change the Sand Blasting nozzle position like 154, 250, 305, 355mm. on the control panel has a switch through this switch we can on/off the Automatic Sand Blasting process. and also we control the speed of the table rotating through the regulator switch. Initially start the air compressor. and fill the abrasive material in the Automatic Sandblasting cabinet and workpiece put into the Automatic Sand Blasting Cabinet on the turntable. the air compressor provides a large volume of high-pressure air that is regulated by the Solenoid valve or ball valve.

For cleaning sensitive regions where dust and debris are not allowed, dustless blasting machine systems offer dust-free blast cleaning. Even though the blasting process takes longer than open blasting, the savings in dust containment time and money frequently make this the best option. Dustless blasting equipment and vacuum sand blasting equipment are manufactured and supplied by Ambica Enterprises in India at competitive prices. A dustless blasting machine is also known as a Vacuum Blasting machine.

Grit Blasting Machine is an abrasive cleaning and surface preparation machine that uses sharp particles. The surface in issue is struck at high velocity by hard, angular particles, removing undesirable material from the surface and exposing a clean, active metal surface.

Sand blasting hose (sometimes named abrasive blasting hoses & blast hoses) is especially utilized to influence positively abrasive media like sand, steel shot, coal slag, & aluminum oxide in abrasive-blasting machines. They contain wide internal tubes certain resist abrasion. Bulk sand blasting hose can be engraved to length, & users can fasten the fittings of their selection to extinction of the hose for attaching it to tools.

Laser rust removal machine, a variousness of laser cleaning, is an efficacious methodology for cleaning up metal segments. Employing a fiber laser cleaning system, rust & distinct adulterations could be instantaneous & released unaccompanied by vandalizing metal undermost.

-

Portable Sand Blasting Machine, as mentioned in the name, means that you can move this machine from one place to another easily. Sandblasting Machines, that are used for blasting cleaning.

Portable Sand Blasting Machine, as mentioned in the name, means that you can move this machine from one place to another easily. Sandblasting Machines, that are used for blasting cleaning. -

Sand blasting machine is used to remove rust and corrosion from metals. This process improves the appearance of a surface and helps maintain its strength. We are the Best Sand Blasting machine manufacturer in India.

Sand blasting machine is used to remove rust and corrosion from metals. This process improves the appearance of a surface and helps maintain its strength. We are the Best Sand Blasting machine manufacturer in India. -

Sand blasting Cabinet Price in India depends on work-piece size, If the work-piece size is small then need a small sand blasting cabinet. If the work-piece size will large then the sand blasting cabinet's size will be large, so the cost will depend on the size of the blast cabinet. Sand blasting Cabinet Manufacturer can reduce cost as per component size.

Sand blasting Cabinet Price in India depends on work-piece size, If the work-piece size is small then need a small sand blasting cabinet. If the work-piece size will large then the sand blasting cabinet's size will be large, so the cost will depend on the size of the blast cabinet. Sand blasting Cabinet Manufacturer can reduce cost as per component size. -

sand Blasting room depends on the capacity of sand blasting machines, cleaning rate, Operating method. We provide a Sand Blasting room, only with today’s complex industrial conditions. more companies are looking to move our custom-made and custom-designed blast rooms. Our highly experienced technical staff can design a blast room to meet your exact specifications and requirements. As professionals, we apply established principles to each job to ensure a blast room totally designed to perform the job you want to be done in the most efficient and economical manner.

sand Blasting room depends on the capacity of sand blasting machines, cleaning rate, Operating method. We provide a Sand Blasting room, only with today’s complex industrial conditions. more companies are looking to move our custom-made and custom-designed blast rooms. Our highly experienced technical staff can design a blast room to meet your exact specifications and requirements. As professionals, we apply established principles to each job to ensure a blast room totally designed to perform the job you want to be done in the most efficient and economical manner. -

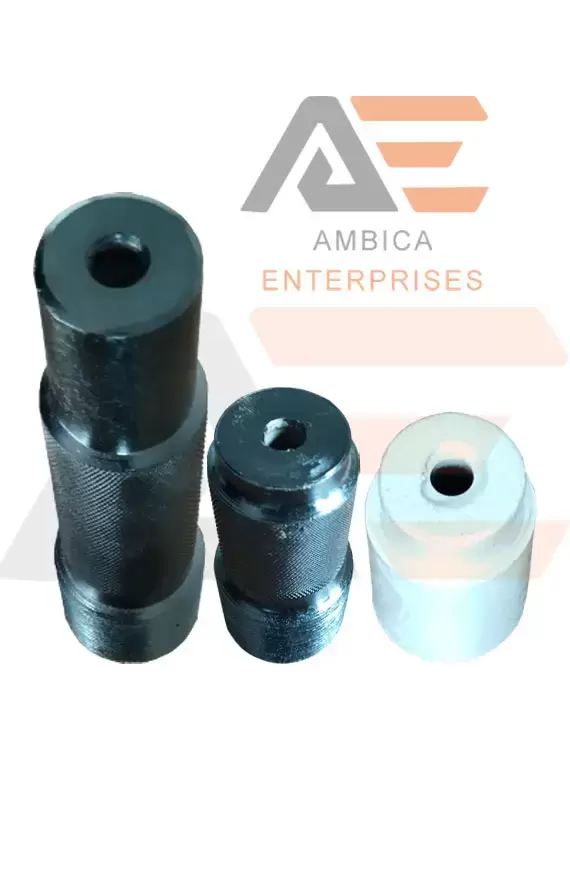

Sand Blasting Nozzle can make a big difference in your system's performance. The bore is very important so you have enough CFM to create pressure that will do your job. The type of nozzle with good air pressure must be selected for getting the job done. On large surfaces, you should use a long venturi which will give you a consistent good size pattern increasing your productivity. Very long venturi nozzles that nozzle called a Bazooka Nozzle are also available for real high pressure and large air and grit output. These are usually preferred in construction such as bridge repainting and so forth. Medium and small venturi sandblaster nozzles are usually used on smaller systems doing small parts like preparation for special coatings.

Sand Blasting Nozzle can make a big difference in your system's performance. The bore is very important so you have enough CFM to create pressure that will do your job. The type of nozzle with good air pressure must be selected for getting the job done. On large surfaces, you should use a long venturi which will give you a consistent good size pattern increasing your productivity. Very long venturi nozzles that nozzle called a Bazooka Nozzle are also available for real high pressure and large air and grit output. These are usually preferred in construction such as bridge repainting and so forth. Medium and small venturi sandblaster nozzles are usually used on smaller systems doing small parts like preparation for special coatings. -

The Bench Top Sand Blasting Cabinet price in India is perfect for a wide variety of removing paint, scale, iron mold, and oxidation. LDPE polymer plastic that converts into outlast steel blasting cabinets. One-piece construction means there are no seams to leak, keeping the blasting cabinet operation contained inside the Bench Top Sand Blasting Cabinet. Inside work area of 22in.W x 12in.H x 18in.D to accommodate a large variety of items. Includes trigger-controlled blast gun with 1/4in. nozzle 18in. rubber blast gloves and protective window underlay. Simply add the abrasive and hook up to an air supply and you are ready to blast. Some assembly required. Bench Top Sand Blasting Cabinet price in India is based on the size of the cabinet, and the size of the sand blasting nozzle. the sand blasting cabinet price is also based on the capacity of the cabinet.

The Bench Top Sand Blasting Cabinet price in India is perfect for a wide variety of removing paint, scale, iron mold, and oxidation. LDPE polymer plastic that converts into outlast steel blasting cabinets. One-piece construction means there are no seams to leak, keeping the blasting cabinet operation contained inside the Bench Top Sand Blasting Cabinet. Inside work area of 22in.W x 12in.H x 18in.D to accommodate a large variety of items. Includes trigger-controlled blast gun with 1/4in. nozzle 18in. rubber blast gloves and protective window underlay. Simply add the abrasive and hook up to an air supply and you are ready to blast. Some assembly required. Bench Top Sand Blasting Cabinet price in India is based on the size of the cabinet, and the size of the sand blasting nozzle. the sand blasting cabinet price is also based on the capacity of the cabinet. -

A Remote control valve is used in Sand Blasting Machine to control the blasting process. In a sandblasting machine with a remote control system, the on or off control of the machine comes in the hands of the operator at the sand Blasting nozzle via deadman Handle. The Deadman handle is connected with a twin line hose. As the deadman handle is activated the twin-line hoses are connected to both the inlet valve and the control handle. In which one hose monitors air traveling towards the nozzle while the other hose controls the air that travels back towards the inlet valve. When the deadman handle is not activated air is released at the base of the handle and no blasting can occur because the system is not pressurized.

A Remote control valve is used in Sand Blasting Machine to control the blasting process. In a sandblasting machine with a remote control system, the on or off control of the machine comes in the hands of the operator at the sand Blasting nozzle via deadman Handle. The Deadman handle is connected with a twin line hose. As the deadman handle is activated the twin-line hoses are connected to both the inlet valve and the control handle. In which one hose monitors air traveling towards the nozzle while the other hose controls the air that travels back towards the inlet valve. When the deadman handle is not activated air is released at the base of the handle and no blasting can occur because the system is not pressurized. -

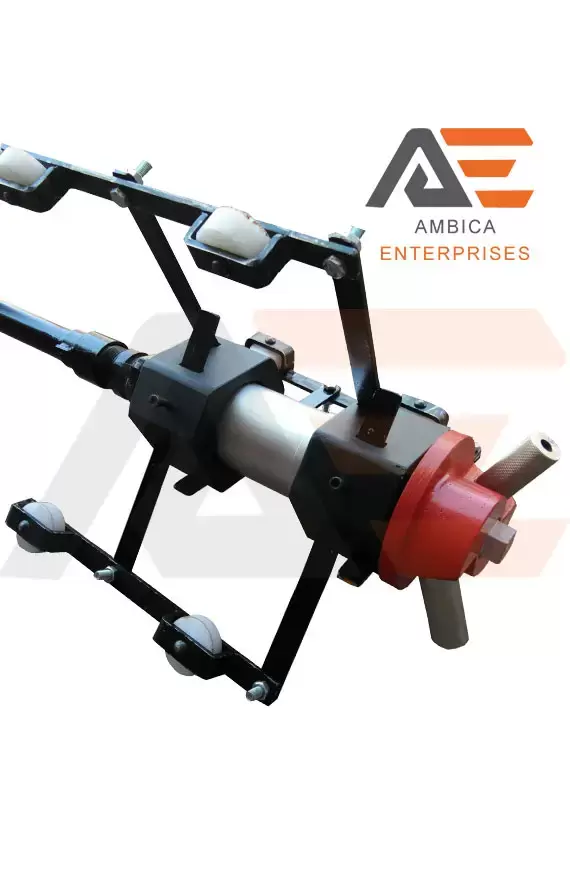

Internal pipe blasting equipment quickly, effectively, and reliably removes corrosion, dust, and another residue from inaccessible areas inside the piping. The operation is simple: a blast pipe is fitted with a pipe tool, and the tool is withdrawn from one end of the pipe to the other. Shot Blaster's proprietary blast technology applies an even, 360° blasting stream to the inner wall, leaving a consistent blast pattern ready for any coating.

Internal pipe blasting equipment quickly, effectively, and reliably removes corrosion, dust, and another residue from inaccessible areas inside the piping. The operation is simple: a blast pipe is fitted with a pipe tool, and the tool is withdrawn from one end of the pipe to the other. Shot Blaster's proprietary blast technology applies an even, 360° blasting stream to the inner wall, leaving a consistent blast pattern ready for any coating. -

The Automatic Sand Blasting Machine has two stepper motor first motor is utilized for rotating the table and the second motor has utilized for moving up and down the gun by reciprocating movement. In the Automatic Sand Blasting Machines, the workpiece is put on the turntable and rotating through the stepper motor first and through the second motor, we can change the Sand Blasting nozzles position up and down, on the control panel have four switches. through switches, we can change the Sand Blasting nozzle position like 154, 250, 305, 355mm. on the control panel has a switch through this switch we can on/off the Automatic Sand Blasting process. and also we control the speed of the table rotating through the regulator switch. Initially start the air compressor. and fill the abrasive material in the Automatic Sandblasting cabinet and workpiece put into the Automatic Sand Blasting Cabinet on the turntable. the air compressor provides a large volume of high-pressure air that is regulated by the Solenoid valve or ball valve.

The Automatic Sand Blasting Machine has two stepper motor first motor is utilized for rotating the table and the second motor has utilized for moving up and down the gun by reciprocating movement. In the Automatic Sand Blasting Machines, the workpiece is put on the turntable and rotating through the stepper motor first and through the second motor, we can change the Sand Blasting nozzles position up and down, on the control panel have four switches. through switches, we can change the Sand Blasting nozzle position like 154, 250, 305, 355mm. on the control panel has a switch through this switch we can on/off the Automatic Sand Blasting process. and also we control the speed of the table rotating through the regulator switch. Initially start the air compressor. and fill the abrasive material in the Automatic Sandblasting cabinet and workpiece put into the Automatic Sand Blasting Cabinet on the turntable. the air compressor provides a large volume of high-pressure air that is regulated by the Solenoid valve or ball valve. -

For cleaning sensitive regions where dust and debris are not allowed, dustless blasting machine systems offer dust-free blast cleaning. Even though the blasting process takes longer than open blasting, the savings in dust containment time and money frequently make this the best option. Dustless blasting equipment and vacuum sand blasting equipment are manufactured and supplied by Ambica Enterprises in India at competitive prices. A dustless blasting machine is also known as a Vacuum Blasting machine.

For cleaning sensitive regions where dust and debris are not allowed, dustless blasting machine systems offer dust-free blast cleaning. Even though the blasting process takes longer than open blasting, the savings in dust containment time and money frequently make this the best option. Dustless blasting equipment and vacuum sand blasting equipment are manufactured and supplied by Ambica Enterprises in India at competitive prices. A dustless blasting machine is also known as a Vacuum Blasting machine. -

Grit Blasting Machine is an abrasive cleaning and surface preparation machine that uses sharp particles. The surface in issue is struck at high velocity by hard, angular particles, removing undesirable material from the surface and exposing a clean, active metal surface.

Grit Blasting Machine is an abrasive cleaning and surface preparation machine that uses sharp particles. The surface in issue is struck at high velocity by hard, angular particles, removing undesirable material from the surface and exposing a clean, active metal surface. -

Sand blasting hose (sometimes named abrasive blasting hoses & blast hoses) is especially utilized to influence positively abrasive media like sand, steel shot, coal slag, & aluminum oxide in abrasive-blasting machines. They contain wide internal tubes certain resist abrasion. Bulk sand blasting hose can be engraved to length, & users can fasten the fittings of their selection to extinction of the hose for attaching it to tools.

Sand blasting hose (sometimes named abrasive blasting hoses & blast hoses) is especially utilized to influence positively abrasive media like sand, steel shot, coal slag, & aluminum oxide in abrasive-blasting machines. They contain wide internal tubes certain resist abrasion. Bulk sand blasting hose can be engraved to length, & users can fasten the fittings of their selection to extinction of the hose for attaching it to tools. -

Laser rust removal machine, a variousness of laser cleaning, is an efficacious methodology for cleaning up metal segments. Employing a fiber laser cleaning system, rust & distinct adulterations could be instantaneous & released unaccompanied by vandalizing metal undermost.

Laser rust removal machine, a variousness of laser cleaning, is an efficacious methodology for cleaning up metal segments. Employing a fiber laser cleaning system, rust & distinct adulterations could be instantaneous & released unaccompanied by vandalizing metal undermost.