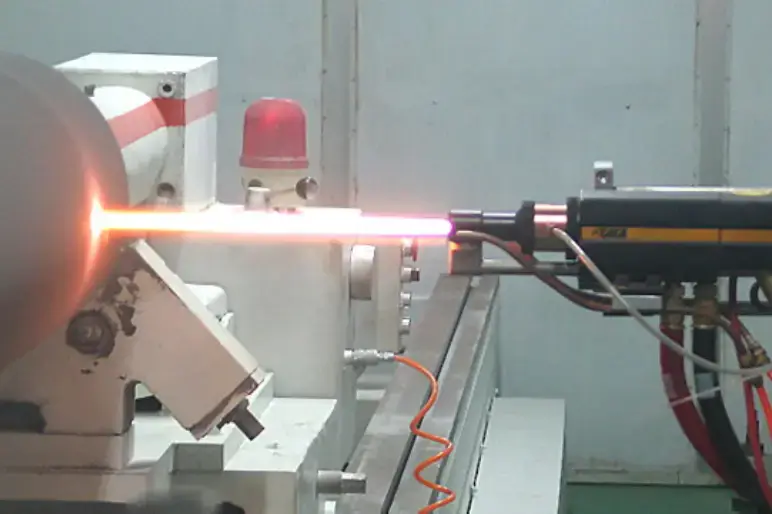

Thermal spray Gun is a cost-effective technique for improving surface characteristics. We support all popular thermal sprinkle processes, with choices to suit your surfacings and all other application elements – such as the size of your run, the scale of your part, environmental concerns, and portability obligation. These guns are used for coating the subjected material with the media(rod, wire, powder).

Arc Spray Gun at a low price in India. Arc Spray Gun uses two consumable wires of metal to fed inside the gun independently. These wires are charged and then an arc is produced between them. The heat from this arc vanishes the incoming wires of metal, after that this heated metal entrained in an air spray from the gun. This entrained molten metal transferred onto the workpiece with the help of compressed air. This process typically employed for heavy coating of metallic on a workpiece.

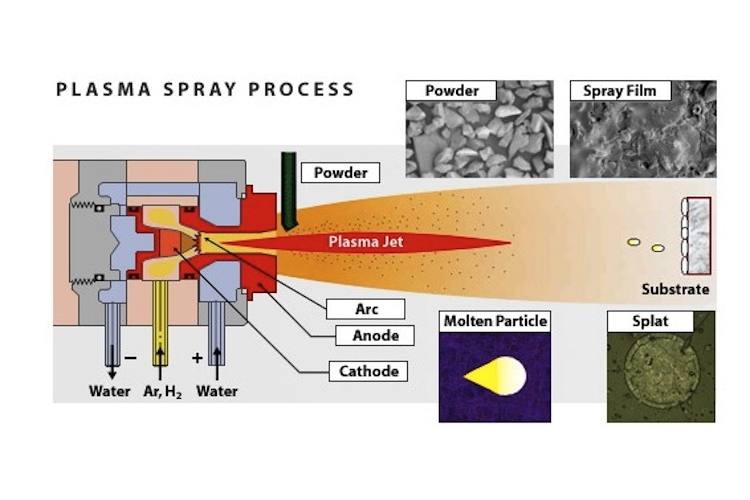

Flame spray gun process in which, the natural material in the form of a single wire, cord, or powder, is melted in an oxy-fuel gas flame. This molten material is atomized by a cone of compressed air and impelled towards the workpiece. In the list of our most exclusive and finest quality services and products are also included these Plasma flame spray services (wire & powder). This service is so much useful in several types of industrial, automobile, and mechanical utilities as they provide excellent coating facilities while giving minimum heat input to the base metal. These Plasma flame spray services (wire, powder & rod) are proved to be very much helpful in corrosion control coatings (aluminum and zinc), Babbitt bearings, decorative coatings, EMI, and RFI shielding for defense, etc.

Wire Flame Spray Gun uses a single wire that is filled into a wire jet flame. The air stream from the jet atomizes the molten particles, propelling them onto the substrate. These technological parameters, such as feedstock, this gun gas composition, and flow rate, and energy input, perform a big role in the relationship between the particles and the substrate. With the wire flame spray technique, the wire spray material is melted in a gaseous oxygen-fuel flame. The fuel gas can be propane, acetylene, or hydrogen.

HVOF Gun (High Velocity Oxygen Fuel Gun) devices are a subset of flame spray gun. There are two differences between the traditional flame spray and HVOF coating process. HVOF Gun uses limited combustion and a widespread nozzle to heat and stimulate the powdered coating material. Characteristic HVOF devices operate at hypersonic gas velocities, i.e. greater than MACH 5. The ultimate velocities afford kinetic energy which helps provide coatings that are extremely dense and very well adhered to in the as-sprayed condition. An HVOF Gun required a very high velocity for the coating process. This high velocity is used to propel the particles at supersonic speed before impact onto the substrate. In the HVOF spray process high combustion pressure and high velocity of gas and particle resulting in high coating quality. There are two types of HVOF guns driven by fuel type like gaseous or liquid in nature.

Metalizing gun is the name given to a thermal spray gun coating process that is used for coating metal on product surfaces. The resultant metallic coatings can be utilized for decorative, protective, or functional purposes. Metalizing gun coatings are also known to be long-lasting, effective, and highly versatile.

A broad range of techniques can be used to apply zinc spray gun coatings to steel including galvanizing, zinc thermal spray gun metallization, electroplating, and zinc-rich paints, among others. These coatings can be used individually or in combination with a paint topcoat for a synergistic effect.

.webp)

Powder Flame Spray Gun for combustion powder spray that can be applying coatings for a variety of purposes, including surface restorations, dimensional restoration.

-

Thermal spray Gun is a cost-effective technique for improving surface characteristics. We support all popular thermal sprinkle processes, with choices to suit your surfacings and all other application elements – such as the size of your run, the scale of your part, environmental concerns, and portability obligation. These guns are used for coating the subjected material with the media(rod, wire, powder).

Thermal spray Gun is a cost-effective technique for improving surface characteristics. We support all popular thermal sprinkle processes, with choices to suit your surfacings and all other application elements – such as the size of your run, the scale of your part, environmental concerns, and portability obligation. These guns are used for coating the subjected material with the media(rod, wire, powder). -

Arc Spray Gun at a low price in India. Arc Spray Gun uses two consumable wires of metal to fed inside the gun independently. These wires are charged and then an arc is produced between them. The heat from this arc vanishes the incoming wires of metal, after that this heated metal entrained in an air spray from the gun. This entrained molten metal transferred onto the workpiece with the help of compressed air. This process typically employed for heavy coating of metallic on a workpiece.

Arc Spray Gun at a low price in India. Arc Spray Gun uses two consumable wires of metal to fed inside the gun independently. These wires are charged and then an arc is produced between them. The heat from this arc vanishes the incoming wires of metal, after that this heated metal entrained in an air spray from the gun. This entrained molten metal transferred onto the workpiece with the help of compressed air. This process typically employed for heavy coating of metallic on a workpiece. -

Flame spray gun process in which, the natural material in the form of a single wire, cord, or powder, is melted in an oxy-fuel gas flame. This molten material is atomized by a cone of compressed air and impelled towards the workpiece. In the list of our most exclusive and finest quality services and products are also included these Plasma flame spray services (wire & powder). This service is so much useful in several types of industrial, automobile, and mechanical utilities as they provide excellent coating facilities while giving minimum heat input to the base metal. These Plasma flame spray services (wire, powder & rod) are proved to be very much helpful in corrosion control coatings (aluminum and zinc), Babbitt bearings, decorative coatings, EMI, and RFI shielding for defense, etc.

Flame spray gun process in which, the natural material in the form of a single wire, cord, or powder, is melted in an oxy-fuel gas flame. This molten material is atomized by a cone of compressed air and impelled towards the workpiece. In the list of our most exclusive and finest quality services and products are also included these Plasma flame spray services (wire & powder). This service is so much useful in several types of industrial, automobile, and mechanical utilities as they provide excellent coating facilities while giving minimum heat input to the base metal. These Plasma flame spray services (wire, powder & rod) are proved to be very much helpful in corrosion control coatings (aluminum and zinc), Babbitt bearings, decorative coatings, EMI, and RFI shielding for defense, etc. -

Wire Flame Spray Gun uses a single wire that is filled into a wire jet flame. The air stream from the jet atomizes the molten particles, propelling them onto the substrate. These technological parameters, such as feedstock, this gun gas composition, and flow rate, and energy input, perform a big role in the relationship between the particles and the substrate. With the wire flame spray technique, the wire spray material is melted in a gaseous oxygen-fuel flame. The fuel gas can be propane, acetylene, or hydrogen.

Wire Flame Spray Gun uses a single wire that is filled into a wire jet flame. The air stream from the jet atomizes the molten particles, propelling them onto the substrate. These technological parameters, such as feedstock, this gun gas composition, and flow rate, and energy input, perform a big role in the relationship between the particles and the substrate. With the wire flame spray technique, the wire spray material is melted in a gaseous oxygen-fuel flame. The fuel gas can be propane, acetylene, or hydrogen. -

HVOF Gun (High Velocity Oxygen Fuel Gun) devices are a subset of flame spray gun. There are two differences between the traditional flame spray and HVOF coating process. HVOF Gun uses limited combustion and a widespread nozzle to heat and stimulate the powdered coating material. Characteristic HVOF devices operate at hypersonic gas velocities, i.e. greater than MACH 5. The ultimate velocities afford kinetic energy which helps provide coatings that are extremely dense and very well adhered to in the as-sprayed condition. An HVOF Gun required a very high velocity for the coating process. This high velocity is used to propel the particles at supersonic speed before impact onto the substrate. In the HVOF spray process high combustion pressure and high velocity of gas and particle resulting in high coating quality. There are two types of HVOF guns driven by fuel type like gaseous or liquid in nature.

HVOF Gun (High Velocity Oxygen Fuel Gun) devices are a subset of flame spray gun. There are two differences between the traditional flame spray and HVOF coating process. HVOF Gun uses limited combustion and a widespread nozzle to heat and stimulate the powdered coating material. Characteristic HVOF devices operate at hypersonic gas velocities, i.e. greater than MACH 5. The ultimate velocities afford kinetic energy which helps provide coatings that are extremely dense and very well adhered to in the as-sprayed condition. An HVOF Gun required a very high velocity for the coating process. This high velocity is used to propel the particles at supersonic speed before impact onto the substrate. In the HVOF spray process high combustion pressure and high velocity of gas and particle resulting in high coating quality. There are two types of HVOF guns driven by fuel type like gaseous or liquid in nature. -

Metalizing gun is the name given to a thermal spray gun coating process that is used for coating metal on product surfaces. The resultant metallic coatings can be utilized for decorative, protective, or functional purposes. Metalizing gun coatings are also known to be long-lasting, effective, and highly versatile.

Metalizing gun is the name given to a thermal spray gun coating process that is used for coating metal on product surfaces. The resultant metallic coatings can be utilized for decorative, protective, or functional purposes. Metalizing gun coatings are also known to be long-lasting, effective, and highly versatile. -

A broad range of techniques can be used to apply zinc spray gun coatings to steel including galvanizing, zinc thermal spray gun metallization, electroplating, and zinc-rich paints, among others. These coatings can be used individually or in combination with a paint topcoat for a synergistic effect.

A broad range of techniques can be used to apply zinc spray gun coatings to steel including galvanizing, zinc thermal spray gun metallization, electroplating, and zinc-rich paints, among others. These coatings can be used individually or in combination with a paint topcoat for a synergistic effect. -

.webp) Powder Flame Spray Gun for combustion powder spray that can be applying coatings for a variety of purposes, including surface restorations, dimensional restoration.

Powder Flame Spray Gun for combustion powder spray that can be applying coatings for a variety of purposes, including surface restorations, dimensional restoration. -

A plasma plume is employed as a high-enthalpy source in a plasma spray gun, whereas thermal energy is created from fuel combustion in the presence of oxygen in an HVOF Spray gun. Plasma spray has more thermal energy than HVOF spray, which aids in the melting of feedstock powder.

A plasma plume is employed as a high-enthalpy source in a plasma spray gun, whereas thermal energy is created from fuel combustion in the presence of oxygen in an HVOF Spray gun. Plasma spray has more thermal energy than HVOF spray, which aids in the melting of feedstock powder. -

The cost of a tungsten carbide coating is presently dependent on the material standing coated. In this affection, Tungsten Carbide coatings are a superior coating.

The cost of a tungsten carbide coating is presently dependent on the material standing coated. In this affection, Tungsten Carbide coatings are a superior coating. -

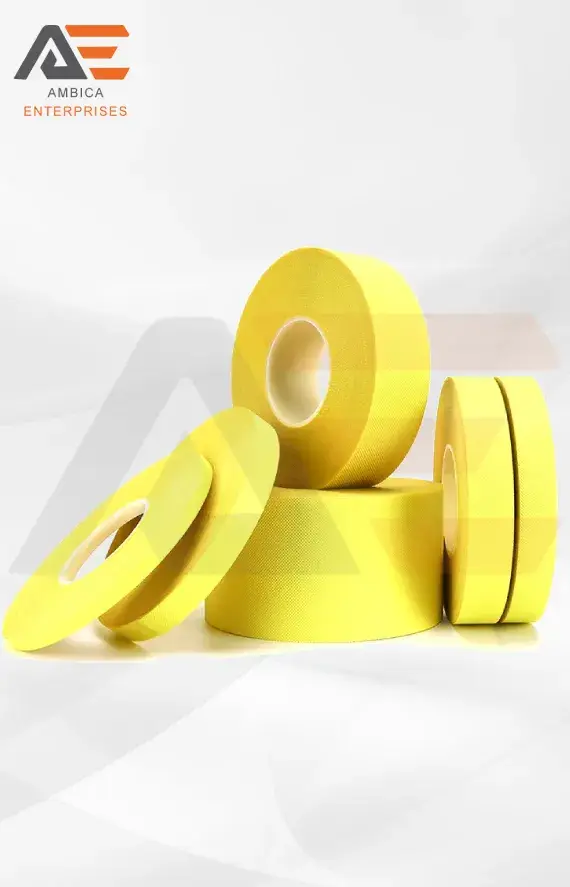

All-purpose thermal spray masking tapes made especially for thermal spray coating, accompanied by a pressure-sensitive silicone adherent system. Products provide excellent conformability and adaptable properties for complex masking needs, & they can tolerate severe temperatures of up to 290C. Pressure-sensitive thermal spray masking tapes are delivered by Ambica Enterprises. To secure a strong binding betwixt the thermal spray masking tape & the component exterior, these materials need to be smoothed & pushed accompanied by pressure.

All-purpose thermal spray masking tapes made especially for thermal spray coating, accompanied by a pressure-sensitive silicone adherent system. Products provide excellent conformability and adaptable properties for complex masking needs, & they can tolerate severe temperatures of up to 290C. Pressure-sensitive thermal spray masking tapes are delivered by Ambica Enterprises. To secure a strong binding betwixt the thermal spray masking tape & the component exterior, these materials need to be smoothed & pushed accompanied by pressure.