Arc Spray Gun

Price Range : ₹ 70K - 7Lakh

Air Transport

Sea Transport

Land Transport

- Production segments that show explicit surface attributes.

- Utilize less costly substrate materials for parts, yet keep up superior surface properties.

- Improve segment administration life.

- Fix existing parts to like-new or better than new condition.

- Rescue mismachined segments.

- Give a superior bond coat in a covering system.

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

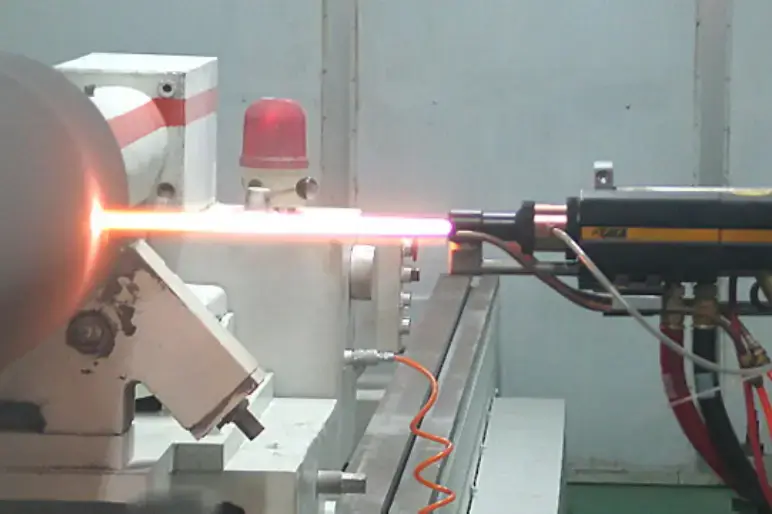

Arc Spray Gun price in India depends on the type of arc spray gun. Two metal wires that are disposable are used by the Arc Spray Gun to separately feed within the gun. After these wires are energized, an arc forms between them. The arc's heat melts the metal wires that are coming in, and then this hot metal is incorporated into the gun's air spray. With the aid of an air compressor, the molten metal is transported onto the workpiece. This method is often used to apply a thick layer of metallic coating on a workpiece.

Arc spray gun includes melting two similar or unlike wires (the coating material) in an arc and speeding them towards a prepared work area using an atomizing gas such as compressed air. Arc spraying is a high-performance wire spraying process that requires an electrically conductive coating substance. Electric or air motors are used to feed twin wires.

Arc Spray Gun Process

In the Arc Spray Gun process, the natural material in the form of metallic wires is melted by means of an electric arc. The molten material is atomized by compressed air and propelled towards the workpiece. This gun is the result of our extraneous R&D Activities which we continually endeavor upon. In this process, the raw material in the form of metallic wires is melted by means of an electric arc. The molten material is atomized by compressed air and propelled towards the workpiece.

The coatings provided in the wire-arc spraying method usually have a greater porosity and lower adhesion intensity than those received from other thermal spray processes, making them of comparatively poorer properties. But, for some purposes, higher measures of porosity are acceptable or even desired. Twin-Wire-Arc spray has a comprehensive range of industrial purposes, categorized according to various wire elements and coating diameters.

Specification of arc Spray Gun

|

Applications / Usage |

Industrial |

|

Air Pressure |

50-70 psi |

|

Nozzle Size |

2 mm |

|

Air Consumption |

9-10 cfm |

|

Air Inlet |

3/8 " |

|

Minimum Quantity |

1 piece |

Arc Spray Gun Working

For feeding metalizing wire to the spray nozzle, the control consul uses two operating modes: pneumatic and electric. The spray gun is hand-held in the first mode, and it pushes the wire into the nozzle to atomize it. The Electric Arc Spray Gun (DC Drive) is connected to an electric-driven motor in the second mode to pull the wire into the spray system. When a spray gun is required in a Lathe Tool post or robot, the Arc Spray Gun (Air Drive) is preferred for manual operation because of its modest weight.

The oldest wire arc spray gun technology is wire arc spray coating. It necessitates feeding the material into the machine via two distinct wires. One of the wires receives a very positive charge, while the other receives a substantially negative charge. During the deposition process, the two wires are continually fed into each other at the device's tip. An electric discharge occurs between the two wires due to the substantial voltage difference between them. The substance at the wire's tip is significantly heated and melted by this spark.

Simultaneously, compressed gas is continually pumped outward towards the tip, and then towards the material to be deposited on the surface. The compressed air will literally pick up the melted metal and toss it directly onto the surface.

Wire Arc Spray Gun Advantage

- Due to decreasing operating costs, coatings for Wire Arc Spray gun is becoming more and more viable.

- More material is produced per hour and a coarser coating is produced compared with the plasma or HVOF processes.

- Wire arc coatings offer on-site solutions and are ideally suited for the dimensional restoration of worn and freshly machined items.

- Hence offers versatility and high reliability.

Features and Benefits of Arc Spray Gun

- Superior flexibility in work configurations.

- Advanced controls deliver.

- Ease of use and reliable results.

- High power allows spraying the hardest wires quickly.

- Spray gun coating tip in fixed position assures consistent, repeatable coatings.

Industrial Uses of Arc Spray Gun

- Power Generation.

- Waste Incineration.

- Electronics.

- Automotive.

Arc Spray Gun Manufacturer in India

We are the leading Manufacturer, Supplier & Exporter of Sand Blasting Machine, Shot Blasting Machine, grit blasting machine, Sand Blasting Cabinet, Suction blasting cabinet, Sand Blasting Nozzle, Sand Blasting Room, Bench Top Sand Blasting Cabinet, thermal Spray gun, metalizing gun, zinc spray gun, flame spray gun, arc spray gun, abrasive media, etc in India at a low price with the best quality for sale. Only "Ambica Enterprises” can provide all solutions for Arc Spray processes & Thermal Spray Equipment with the application needed for the arc spray coating in India.

- Delivery Time- Minimum Time

- Port Of Dispatch- Thar Dry Port

- Production Capacity- 2-3 Per Month

- Packaging Details- Box

- Payment Terms- L/C (Letter of Credit)/T/T (Bank Transfer)