Zinc Wire is excellent material choices for corrosion protection in both atmospheric and marine environments.

Babbitt wires are utilized in the thermal spray for the thermal coating process. The thermal spray uses an electric arc wire spray or flame wire spray process for thermal spray coating. White metals can be alluded to as Babbitt. These white materials can be tin or lead, antimony, or copper. This wire has both delicate and hard pieces and they offer wonderful low contact obstruction and wear opposition.

Molybdenum wire is generally used for vehicle and machine parts that are introduced to high mechanical loads with remarkably incredible sliding properties joined with astounding wear resistance.

Aluminum wires are attracted to an assortment of distances across for use in electric circular segment wire and burning wire splash frameworks. The coatings delivered by these aluminum wire has various valuable attributes that incorporate protection from climatic, substance, and warmth erosion.

For several coating processes, thermal spray wire is employed as the feed material including flame wire (combustion wire) spray and electric arc spray, thermal spray gun. We provide thermal spray wires made of alloys based on nickel. One layer at a time to prevent these issues.

Metalizing Wire and Arc Spray Wire are further names for thermal spray wire. Metalizing Wire serves as a feedstock for a variety of thermal Spray coating techniques, including flame wire (combustion wire) and electric arc spraying. A crucial factor in the application is the wire diameter of the Thermal Spray wire.

Numerous Nickel Wire is available from us and is utilized in RTD sensors, resistors, rheostats, voltage control relays, heating elements, potentiometers, and other parts. Engineers base their designs on each alloy's special characteristics. These include magnetic attraction, resistance to oxidation or corrosive conditions, high tensile strength, thermoelectric characteristics, coefficient of expansion, and high tensile strength. Wires are available without insulation or with a film coating.

The Copper Wire, which is frequently employed in the thermal spray coating process to give resistance to neutral climatic conditions and seawater ecosystems, is a corrosion-resistant element in a non-oxidizing environment.

-

Zinc Wire is excellent material choices for corrosion protection in both atmospheric and marine environments.

Zinc Wire is excellent material choices for corrosion protection in both atmospheric and marine environments. -

Babbitt wires are utilized in the thermal spray for the thermal coating process. The thermal spray uses an electric arc wire spray or flame wire spray process for thermal spray coating. White metals can be alluded to as Babbitt. These white materials can be tin or lead, antimony, or copper. This wire has both delicate and hard pieces and they offer wonderful low contact obstruction and wear opposition.

Babbitt wires are utilized in the thermal spray for the thermal coating process. The thermal spray uses an electric arc wire spray or flame wire spray process for thermal spray coating. White metals can be alluded to as Babbitt. These white materials can be tin or lead, antimony, or copper. This wire has both delicate and hard pieces and they offer wonderful low contact obstruction and wear opposition. -

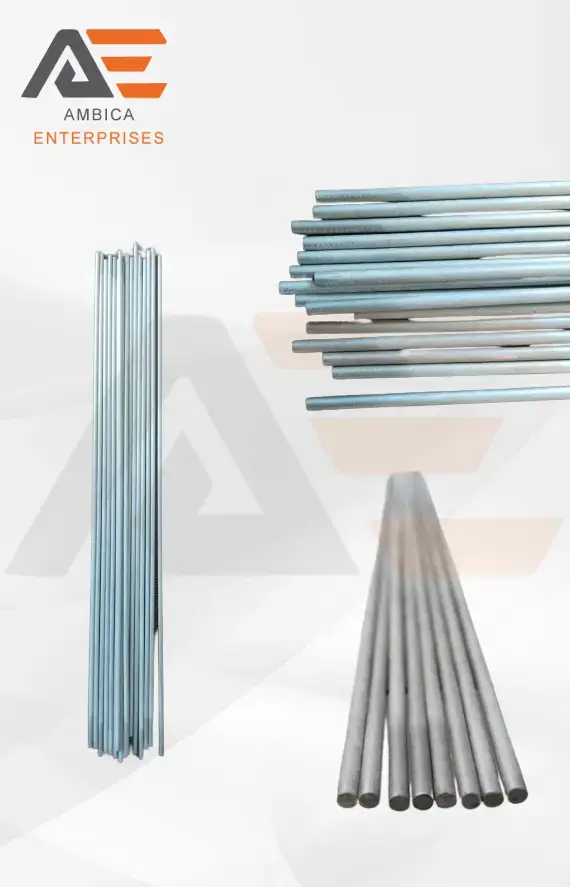

Molybdenum wire is generally used for vehicle and machine parts that are introduced to high mechanical loads with remarkably incredible sliding properties joined with astounding wear resistance.

Molybdenum wire is generally used for vehicle and machine parts that are introduced to high mechanical loads with remarkably incredible sliding properties joined with astounding wear resistance. -

Aluminum wires are attracted to an assortment of distances across for use in electric circular segment wire and burning wire splash frameworks. The coatings delivered by these aluminum wire has various valuable attributes that incorporate protection from climatic, substance, and warmth erosion.

Aluminum wires are attracted to an assortment of distances across for use in electric circular segment wire and burning wire splash frameworks. The coatings delivered by these aluminum wire has various valuable attributes that incorporate protection from climatic, substance, and warmth erosion. -

For several coating processes, thermal spray wire is employed as the feed material including flame wire (combustion wire) spray and electric arc spray, thermal spray gun. We provide thermal spray wires made of alloys based on nickel. One layer at a time to prevent these issues.

For several coating processes, thermal spray wire is employed as the feed material including flame wire (combustion wire) spray and electric arc spray, thermal spray gun. We provide thermal spray wires made of alloys based on nickel. One layer at a time to prevent these issues. -

Metalizing Wire and Arc Spray Wire are further names for thermal spray wire. Metalizing Wire serves as a feedstock for a variety of thermal Spray coating techniques, including flame wire (combustion wire) and electric arc spraying. A crucial factor in the application is the wire diameter of the Thermal Spray wire.

Metalizing Wire and Arc Spray Wire are further names for thermal spray wire. Metalizing Wire serves as a feedstock for a variety of thermal Spray coating techniques, including flame wire (combustion wire) and electric arc spraying. A crucial factor in the application is the wire diameter of the Thermal Spray wire. -

Numerous Nickel Wire is available from us and is utilized in RTD sensors, resistors, rheostats, voltage control relays, heating elements, potentiometers, and other parts. Engineers base their designs on each alloy's special characteristics. These include magnetic attraction, resistance to oxidation or corrosive conditions, high tensile strength, thermoelectric characteristics, coefficient of expansion, and high tensile strength. Wires are available without insulation or with a film coating.

Numerous Nickel Wire is available from us and is utilized in RTD sensors, resistors, rheostats, voltage control relays, heating elements, potentiometers, and other parts. Engineers base their designs on each alloy's special characteristics. These include magnetic attraction, resistance to oxidation or corrosive conditions, high tensile strength, thermoelectric characteristics, coefficient of expansion, and high tensile strength. Wires are available without insulation or with a film coating. -

The Copper Wire, which is frequently employed in the thermal spray coating process to give resistance to neutral climatic conditions and seawater ecosystems, is a corrosion-resistant element in a non-oxidizing environment.

The Copper Wire, which is frequently employed in the thermal spray coating process to give resistance to neutral climatic conditions and seawater ecosystems, is a corrosion-resistant element in a non-oxidizing environment. -

Bronze Wire is composed of copper and tin which makes it strong, corrosion and fatigue resistant, and it can withstand harsh conditions.

Bronze Wire is composed of copper and tin which makes it strong, corrosion and fatigue resistant, and it can withstand harsh conditions. -

A unusual combination of superior corrosion resistance & heightened stability from cryogenic temperatures down to 1800F (982C) characterizes Alloy 625, an austenitic nickel, chromium, molybdenum, & niobium alloy. Because molybdenum & niobium are current, the nickel-chromium matrix solidifies in a resolution, offering Alloy 625 its stability. Treatments for showers toughening are thus not mandated.

A unusual combination of superior corrosion resistance & heightened stability from cryogenic temperatures down to 1800F (982C) characterizes Alloy 625, an austenitic nickel, chromium, molybdenum, & niobium alloy. Because molybdenum & niobium are current, the nickel-chromium matrix solidifies in a resolution, offering Alloy 625 its stability. Treatments for showers toughening are thus not mandated.