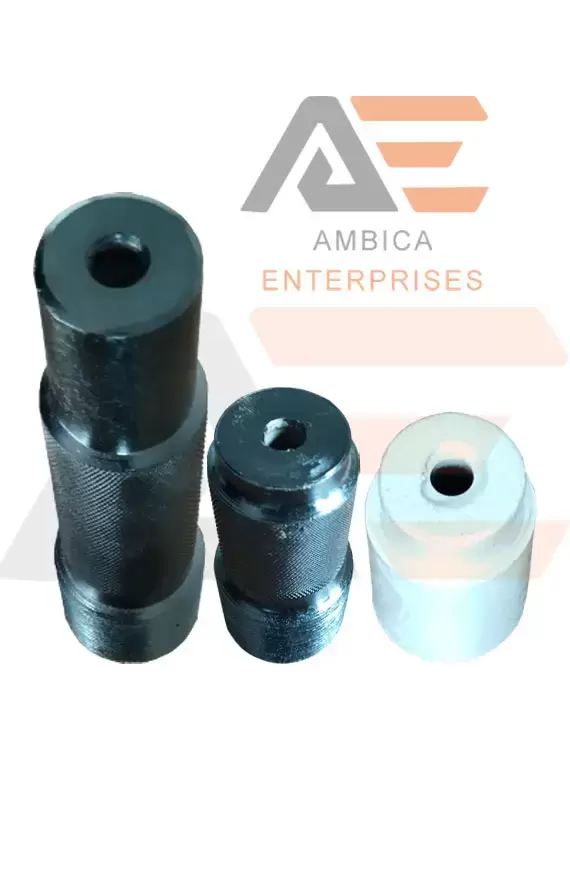

Sand Blasting Nozzle

Price Range : ₹ 3k - 20k

Air Transport

Sea Transport

Land Transport

- Dry, Wet, Suction Blasting

- Scrubber

- Descaling

- Spray Drying

- Abrasive Waterjet and Slurry Jet

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

Sand Blasting Nozzle Price in India

Sand blasting nozzle price in India depends on the size and type of the sand-blasting nozzle. and the capacity of the speed of the nozzle and the diameter of the nozzle. Sand Blasting Nozzle can make a big difference in your system's performance. The bore is very important so you have enough CFM to create pressure that will do your job. The type of nozzle with good air pressure must be selected for getting the job done. On large surfaces, you should use a long venturi which will give you a consistent size pattern increasing your productivity. Very long venturi nozzles that nozzle called a sand blasting nozzle holders are also available for real high pressure and large air and grit output.

These are usually preferred in construction such as bridge repainting and so forth. Medium and small venturi sand blaster nozzle is usually used on smaller systems doing small parts like preparation for special coatings. Several materials are appropriated for sand blasting nozzles such as aluminum oxide which is regularly called ceramic or tungsten carbide which is a high-density metal for heavier abrasion media. Boron sand blasting nozzles are usually used with very abrasive media like aluminum oxide silicon carbide or hardened steel grit.

The only more abrasion-resistant material is rooted. On these routes sand blasting nozzles are usually used in the heaviest abrasives and production areas. They wear better than anything else available.

Sand Blast Nozzle

Angled sand blast nozzles are becoming more popular for cleaning inside of pipes or housings where the straight nozzles can't be productive or even perform the desired coverage. There are many selections available at different angles and even a few with a reverse angle. Sand blasting nozzles are a necessary part of any sand blasting machine operation. The type of nozzle you use will depend on the blast media you are using, the surface you are blasting, and the equipment you are using.

There are many different types of nozzles, The most important thing to remember when selecting a nozzle is to match the nozzle to the blast media and the surface you are blasting. If you use the wrong nozzle, you may not get the results you want, and you may even damage the surface you are trying to clean.

Type of Sand Blasting Nozzle

1. Straight Bore Nozzle

Straight-bore nozzles produce a tight blast pattern, making them ideal for spot blasting and blast cabinet work. These are great for tiny jobs like cleaning parts, shaping weld seams, cleaning handrails, steps, grillwork, and cutting stone, as well as other materials.

2. Venturi Bore Nozzle

The Venturi Bore Nozzles produce a wide blast pattern and up to a 100% increase in abrasive velocity for a given pressure. When blasting larger surfaces, venturi nozzles are the ideal option for increased productivity. When compared to straight-bore nozzles, long venturi-style nozzles deliver a 40 percent boost in productivity and a 40 percent reduction in abrasive consumption.

3. Double Venturi Sand Blasting Nozzle

The Double Venturi type is made up of two sand blasting nozzles in sequence with a gap and holes in between to allow ambient air to enter the nozzle's downstream segment. The nozzle's exit end is also wider than a standard nozzle's. Both changes are aimed at improving the size of the blast pattern while minimizing abrasive velocity loss.

4. Wide Throat Nozzle

Nozzles with a large entering throat and a big, diverging exit bore are known as Wide Throat Nozzles. When used with the same-sized hose, they can boost production by 15% when compared to nozzles with a smaller throat.

When wide-throat sand blasting nozzles are combined with a bigger diverging exit bore, they can be utilized at greater pressures to produce a pattern that is up to 60% larger while using less abrasive.

5. XL Performance nozzle

XL performance nozzles boost the velocity of abrasive particles, allowing for a longer stand-off distance and higher production rates and efficiencies. Angle nozzles are also an excellent idea to have on hand for confined spaces like bridge lattices, under flanges, or inside pipelines.

Many operators waste time and abrasive while they wait for ricochet to finish the work. The brief time required to switch to an angle nozzle is always quickly recovered, resulting in a shorter overall workday.

Tungsten Carbide Sand Blasting Nozzle

When it comes to cost and durability, tungsten carbide sand blasting nozzles are the best option. Most abrasives work well with these tough and lasting blast nozzles. The fast velocity of the liquid through the tungsten carbide nozzle in high-pressure spraying applications causes the orifice to wear out very quickly. The flow rate will rise as the orifice gets bigger.

Surprisingly, nozzle wear, poor product quality, or uneven spray dispersion can result in the waste of tens of thousands or even hundreds of thousands of dollars in extra adhesives, coatings, paint, and chemicals. The increased use of pumps will also result in higher electricity prices. Longer wear life can be achieved by using spray tips made of a tougher substance. The tungsten carbide resistance ratio is up to 250 times greater than brass, according to the abrasion resistance ratio chart.

A tungsten carbide nozzle may be a superior alternative if overall nozzle endurance is a major concern, such as in a hard blasting environment because it reduces the chance of cracking upon impact.

Boron Carbide Sand Blasting Nozzle

Due to the exceptional durability of the boron carbide material used in its manufacturing, the Boron Carbide sand Blasting Nozzle shows little wear. Because of their exceptional wear resistance, the boron carbide nozzle endurance provides significant cost savings.

boron carbide blasting nozzles for a wide range of common and unique uses. We have been able to steadily increase the number of blasting nozzles we offer and provide the best possible technologically advanced goods thanks to ongoing research and market analysis.

Only diamond and cubic boron nitride are harder technical materials than boron carbide, which gives it outstanding abrasion resistance. Even in applications utilizing extremely hard abrasives like corundum and silicon carbide, Boron Carbide Sand Blasting Nozzles have an incredibly long service life when used properly.

Sand Blasting Nozzle Size

Different thread sizes are available for many different sand blasting machines. The most popular thread is a 1-1.25-inch national male pipe thread. Most of the bigger sandblasting nozzles like- sand blasting nozzle 8mm price have a thread. There is also a course 50 MM thread also called the construction thread which is much more course and a little bigger.

The smaller thread is a 3/4 inch national male pipe treat for the smaller shot blasting machine. These are used with 1/2 inch I.D. and 5/8 inch I.D. blast hose. The small hobby technique sandblasters normally are non-threaded and take a special holder. there are different sizes of O.D. and I.D. available.

Sand Blasting Nozzle for Sale

Our sandblasting nozzles are on the market and they are made of premium-quality materials in order to endure and perform efficiently. They are ideal for tasks such as cleaning and surface preparation. The use of advanced technology with strict quality standards ensures the reliability of the product. The purchase of these nozzles is the potentiality of which citizens benefit from the consideration of the issues of business development.

Sand Blasting Nozzle latest price in India depends on the type of sand-blasting nozzle. Ambica Enterprises provide all types of sand blasting machine nozzles like; straight bore, venturi, double venturi, boron carbide, and tungsten carbide sand blasting nozzles in India at a low prices for sale.

Sand Blasting Nozzles Manufacturer in India

In India, high-quality sand blasting nozzles are manufactured with advanced technology and strict quality control. These nozzles are made for various industrial uses, such as cleaning and surface preparation. The focus on innovation and customer satisfaction makes these nozzles reliable for businesses.

Ambica Enterprises is a leading manufacturer, supplier & exporter of sand blasting nozzles in India, sand blasting machine, shot blasting machine, grit blasting machine, sand blasting cabinet, suction blasting cabinet, portable sand blasting machine, shot blasting room, thermal spray gun, metalizing gun, flame spray gun, arc spray gun, zinc spray gun in Jodhpur, Rajasthan, India at a low price for sale.