Tungsten Carbide Coating

Price Range : ₹ 60K-1Lakh

Air Transport

Sea Transport

Land Transport

- In different paper production processes.

- In steel, and metals production.

- In power generation oil & gas Engineering Industrial.

- In abrasive grinding papers, & polishing papers.

- For cutting and machining tools.

- Used for varying surface finishing or from large to small components.

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

The cost of a tungsten carbide coating is presently dependent on the material standing coated. In this affection, Tungsten Carbide coatings are a superior coating. tungsten carbide coatings are frequently selected at the time regions contain experience enduring deterioration by wear or corrosion & coating is additionally cost efficacious than purchasing new. In similar statuses, tungsten carbide coatings are a more reasonable & achievable resolution.

They are mainly employed toward what exceptional wear resistance is major elementary; as its wear resistance reaches its additional automatic effects.

Tungsten Carbide (WC) is an especially difficult ceramic material in the formation of grey acceptable powder bits. This material displays superior wear, scrape, & scrape resistance owing to its heightened solidity. It protects externals from detriment & further external launched invasions similar to rust, corrosion, & exhaustion. Existing ceramic, in essence, Tungsten Carbide is powerfully durable owing to its more elevated melting point.

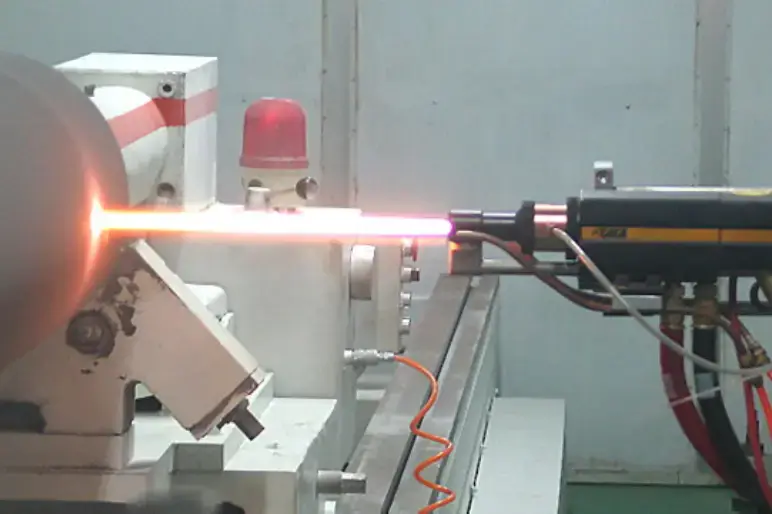

Tungsten Carbide Thermal Spray Process

Tungsten carbide coatings are performed via the HVOF thermal spray gun process. inside this method, fuel gas & oxygen are burned in a heightened-pressure enclosure accomplishing temperatures up to 5,600F (3,093C). The resultant hot, elevated-pressure gas is discharged via a short-diameter nozzle & revved down an extended cask at rapid accelerations. Tungsten carbide powder (or a further powder coating material, as the scheme mandates) is insinuated into the nozzle, toward what the bits deviate by quickening gases, gaining accelerations up to 3,000 ft/sec.

Tungsten Carbide Coating Process

Tungsten carbide conceivable involved in engaging dissimilar techniques together with a detonation gun (Hvof d-gun) & high-velocity oxygen fuel spray (HVOF gun). There are advantages for individual processes.

D-Gun Tungsten Carbide Coating

Tungsten carbide coatings existed devoted escorted by detonation gun (d-gun) concerns an undisturbed spark to kindle acetylene gas escorted by tungsten carbide powder discharging down a cask & dock on jobpiece. As more delicate bits in the d-gun coating spread, layer assembles at an instantaneous acceleration.

The usage of d-gun thermal spray for carbide coatings oversees a powerful bond stability escorted by alternatives for consistency & raggedness to deliver suitable corrosion, wear, & decay conservancy.

HVOF Tungsten Carbide Coating

Tungsten carbide coatings engaged accompanied by high-velocity Oxygen Fuel Spray (HVOF) contain a heightened kinetic fuel existing dispatched into powder scraps as a thermal spray. Tungsten Carbide Powder bits are approvingly energetic whereas at the time they slap jobpiece, speed reaches naught & kinetic fuel is engaged. This affects bits annihilate & directly connecting accompanied by jobpiece. As finer bits in HVOF coating spread, the coating constructs at an immediate speed.

The usage of HVOF thermal spray for carbide coatings guides to substantial bond stability, quiet porosity, sufficient rust resistance, wonderful wear resistance, opposition to decay, & descending residual tension.

Further, the HVOF thermal spray process outcomes in somewhat custom-make coatings for the reason that wear resistance, stability, & denseness hang on the importance trace & cereal measure of scraps & on kinds & proportions of metallic binder engaged. This permits you to adjust the denseness & additional belongings of the carbide coatings to assemble thorough necessities for a yielded thing.

Tungsten Carbide Coating Benefits

- Tungsten carbide thermal spray coatings improve assistance life of product.

- Coating technology is efficient & trustworthy.

- Precaution is opposed to an expansive assortment of external impairment.

- It proposes a fine mixture of automatic & metallurgical effects.

Tungsten Carbide Coating in India

We are the Leading manufacturer and supplier of Tungsten carbide coating machines, thermal spray guns, HVOF guns, arc spray guns, metal spray guns, thermal spray powder, Tungsten carbide powder, ceramic powder, sand blasting machine, abrasive blasting machine equipment, tumblast shot blasting machine, pipe cleaning shot blasting machine, portable grit blasting machine, blast room system, abrasive blasting cabinet, paint booth, air compressor, dust collector, mineral powder, dolomite powder, limestone powder, gypsum powder, calciate powder, thermal spray wire, babbit wire, zinc wire, copper wire, abrasive media, copper slag, abrasive garnet sand, steel grit, steel shot, quartz sand, glass beads, etc.