HVOF Coating for Landing Gear Legs

In the aerospace sector, HVOF (High-Velocity Oxygen Fuel) coating is frequently utilized to provide protective coatings to components like landing gear legs.

Granite Engraving Machine Price

Granite engraving machine price can differ widely based on several elements, including the kind of machine, its features, & specifications of granite engraving machine in India.

Belt Type Shot Blasting Machine

A bunch of smallish elements & thin-wall castings, ceramics, delicate iron & aluminum alloy castings, & various job piece surface cleaning applications utilize belt type shot blasting machines. Carefully arranging multiple smallish jobpieces subsequently to severally other on a wire mesh belt can improve machine output.

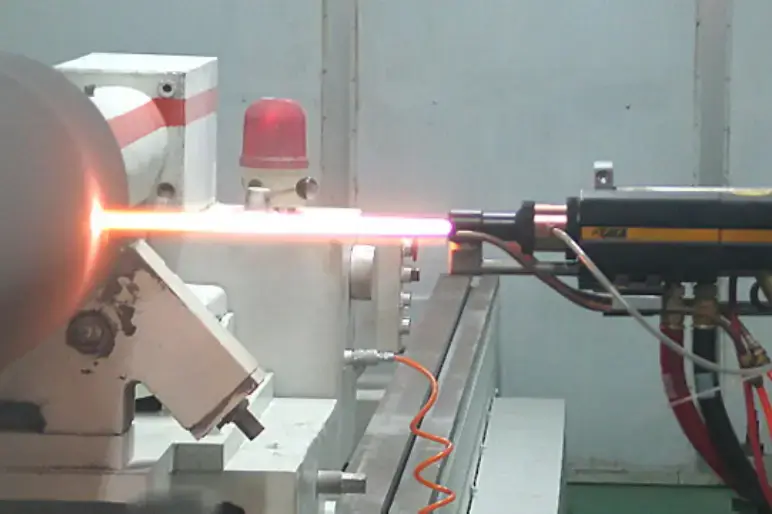

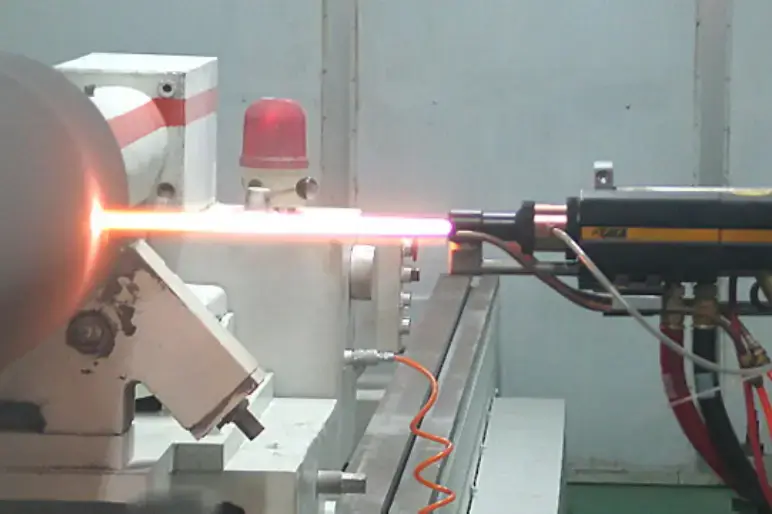

Tungsten Carbide Thermal Spray Coating

tungsten carbide thermal spray coating is a widely utilized coating material for a wide range of products in many different sectors. Equal amounts of carbon atoms and tungsten atoms make up tungsten carbide. With twice the density of steel, it is almost twice as strong nearly halfway between that of lead and gold. The (high-velocity oxy fuel) HVOF tungsten carbide coating forms an instant bond with the substrate upon application, offering exceptional wear resistance and bond strength.

-

In the aerospace sector, HVOF (High-Velocity Oxygen Fuel) coating is frequently utilized to provide protective coatings to components like landing gear legs.

In the aerospace sector, HVOF (High-Velocity Oxygen Fuel) coating is frequently utilized to provide protective coatings to components like landing gear legs. -

Granite engraving machine price can differ widely based on several elements, including the kind of machine, its features, & specifications of granite engraving machine in India.

Granite engraving machine price can differ widely based on several elements, including the kind of machine, its features, & specifications of granite engraving machine in India. -

A bunch of smallish elements & thin-wall castings, ceramics, delicate iron & aluminum alloy castings, & various job piece surface cleaning applications utilize belt type shot blasting machines. Carefully arranging multiple smallish jobpieces subsequently to severally other on a wire mesh belt can improve machine output.

A bunch of smallish elements & thin-wall castings, ceramics, delicate iron & aluminum alloy castings, & various job piece surface cleaning applications utilize belt type shot blasting machines. Carefully arranging multiple smallish jobpieces subsequently to severally other on a wire mesh belt can improve machine output. -

tungsten carbide thermal spray coating is a widely utilized coating material for a wide range of products in many different sectors. Equal amounts of carbon atoms and tungsten atoms make up tungsten carbide. With twice the density of steel, it is almost twice as strong nearly halfway between that of lead and gold. The (high-velocity oxy fuel) HVOF tungsten carbide coating forms an instant bond with the substrate upon application, offering exceptional wear resistance and bond strength.

tungsten carbide thermal spray coating is a widely utilized coating material for a wide range of products in many different sectors. Equal amounts of carbon atoms and tungsten atoms make up tungsten carbide. With twice the density of steel, it is almost twice as strong nearly halfway between that of lead and gold. The (high-velocity oxy fuel) HVOF tungsten carbide coating forms an instant bond with the substrate upon application, offering exceptional wear resistance and bond strength.