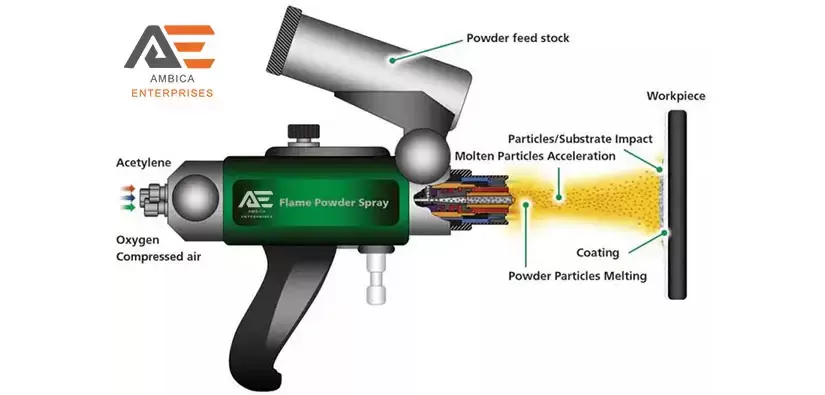

The powder flame spray gun process works a comparable technique as the Flame Wire Spray method, but the wire flame spray gun feedstock is replaced by a powder. The main benefit of this method is that a much wider variety of materials (such as nickel or cobalt-based self Fixing composites or ceramic substances) can be easily treated into powder form providing a greater choice of coatings. Many compounds are difficult or cannot be presented in a wire form and for this purpose, it was produced.

Working behind a powder flame spray gun that relies on the chemical reaction between oxygen and combustible combustion to produce a flame spray gun source. This flame source produces a gas stream by temperature in excess of 3,000°C with correctly balanced conditions between oxygen and acetylene. The feedstock material to be spattered is fed into the flame in the form of a powder to melt and the thermal extension of the flaming is then used to atomize and stimulate the particles onto the component.

Properties Of Coating Powders

When a material is flame-sprayed, new and complex material is produced. This is the basis that the quality of coating depends upon the quality of the powder. A slight variation in powder chemistry can greatly influence the property of the last coating. The particle size distribution in a powder can change the density plus porosity of the coating. Our Powders meet excellent examples of chemical composition, particle shape & size, flow rate & purity.

We supply all required equipment to optimize the use of aFlame Powder Spray System, including:

- Flame powder spray guns.

- Gas Control arrangements (Mass Flow Control).

- Hose.

- Cable.

- Powder feeder

Powder Flame Spray Gun 5PS-II

The 5PS-II is suitable for all-purpose use in that it can apply a wide variety of coating materials such as self-fluxing composites, ceramics, self-bonding elements, and conventional materials such as mild steel shots, shot blasting machine, stainless steel shots, bronze wire, aluminum-based, and nickel-based alloys. Designed for handheld operation, the 5PS-II is lightweight and operates a handle for operator comfort and safety. A tool post attachment is also included to rest the gun during workpiece changeover.

With its built-in powder feed canister, a thermal spray system utilizing the 5PS-II Flame Powder Spraygun is an attractive choice for workshops with occasional surfacing activity or when an economical expenditure is required.

Powder Flame Spray Gun 6PS-II

The 6PS-II gun range is fit for all-purpose use in that it can apply a wide range of coating materials such as self-fluxing compounds, ceramics, self-bonding elements, and common materials such as mild steel shots, stainless steel shots, bronze wire, aluminum oxide, nickel alloys.

A regular and accurate supply of powder is fed from the SPF-700 powder feeder to the gun enabling you to mount or manually spray in practically any position without changing the powder feed rates.