Metalizing Gun

Price Range : ₹ 45K - 6Lakh

Air Transport

Sea Transport

Land Transport

- Massive steel structures like bridges need to be shielded from the elements.

- Weather protection for offshore oil platforms.

- boosting of the pipeline.

- preventing concrete from having steel reinforcement.

- a boiler needs repair.

- Refinishing a deck.

- Abradability.

- Protection against corrosion.

- Components that have worn out are fixed.

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

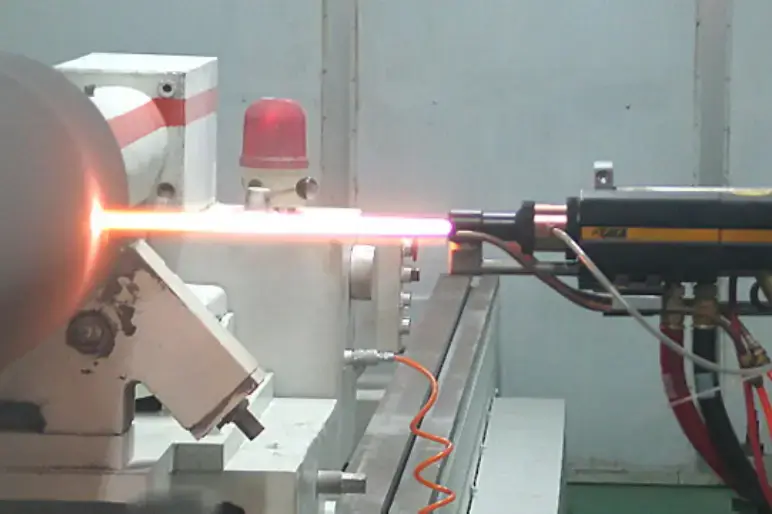

Metalizing gun is the name given to a thermal spray gun coating process that is used for coating metal on product surfaces. The resultant metallic coatings can be utilized for decorative, protective, or functional purposes. Metalizing gun coatings are also known to be long-lasting, effective, and highly versatile.

A flame spray gun is used in metalizing Spray Gun equipment, and a pair of metal wires are brought together at an intersection point. An electrical current is passed through each of the metal wires separately. An electric arc is formed at the point where the two wires connect. The electric arc has enough power to melt the wires. The junction site is targeted using a jet or stream of compressed gas, commonly air. The air atomizes the molten metal into particles, which are then sprayed onto a substrate in a spray stream. Separately charged wires are continually propelled forward, and the electrical arc is maintained at the intersection site because the arc's energy consumes the wire ends. As the metalized particles impact and disperse throughout the substrate, a coating is created. Coating equipment and structures to prevent corrosion are one of the most prevalent applications for spray metalizing technology. Prior to applying the metalizing coating, the building, equipment, or other substrate is usually sandblasted. Sandblasting is used to remove old coatings and corrosion from the substrate. In the setting where the spray metalizing apparatus is in use, the sand blasting machine also produces a lot of dust, grit, and other airborne particles. Due to the spraying components of the metalizing procedure, there is also an over-spray effect from the spray stream of molten metal particles.

Specification of Metalizing gun

|

Type Of Metal |

ALUMINIUM |

|

Brand |

Ambica Enterprises |

|

Type Of Thermal Spraying |

Wire Flame Spray Gun |

|

Color |

RED |

|

Applications |

Industrial, LPG Cylinders |

|

Metal Spray Equipments |

Flame Spray |

|

Automation Grade |

Manual |

|

Air Consumption |

70-100 psi |

|

Nozzle Size |

3.15 mm |

|

Form |

Wire |

|

Air Pressure |

8-9 cfm |

|

Air Inlet |

3/8" |

|

Sound Pressure |

115 -150 dB |

Metalizing gun process

Ambica Enterprises deals in three types of metalizing processes:

- Electric Arc spray gun

- Powder flame spray gun

- Wire Flame Spray Gun

Arc Spray Gun

In the arc spray gun type of process, we utilize two metallic wires that are electrically charged with opposing polarity as the coating feedstock. This will cause them to throw a molten arc between each other. We will next inject still gas or high-velocity air to trigger the atomization of the now-molten material and move it onto the substrate to form the coating. If you opt for the electric arc spray process, we can spray any type of metal that has melting points below 10,000°F.

Depending on the equipment being used and the material being applied, we provide metallic coatings with either semi-metallurgical bonds or mechanical bonds up to 5000 P-S-I. Distortion will not occur because the substrate is not exposed to a high temperature of over 250°F.

Powder Flame Spray Gun

In the powder flame spray gun process, the fundamental principle of the heat source is the same as wire spray except that powders are fed through a flame and propelled by high-velocity oxygen or air onto a substrate. Any powdered metal or ceramic with a melting point below 5500°F. can be sprayed, just like the metalizing process. Abradable coatings and spray/fuse hard surfacing are the most common applications for this method.

Wire Flame Spray Gun

In the wire flame spray gun process, we feed the spray material in wire form into a fuel gas-oxygen flame where it is melted by the heat (temperature up to 5500°F) of that combustion. Compressed air is focused around the flame spray gun, atomization of the molten material into fine spherical particles and propelling these particles at high velocity onto the substrate.

When we regulate the feeding rate of the wire through the flame, we may manipulate the atomization and melting of metals with varied melting points. We can spray any wire that has a melting point of less than 2200°C if you choose this procedure.

Ambica Enterprises is the leading manufacturer, supplier, and exporter of sand blasting machine, shot blasting machine, grit blasting machine, Metalizing Gun and flame spray guns with the best quality at low prices in India. shot blasting machine price in India depends on the type of shot blasting machine.