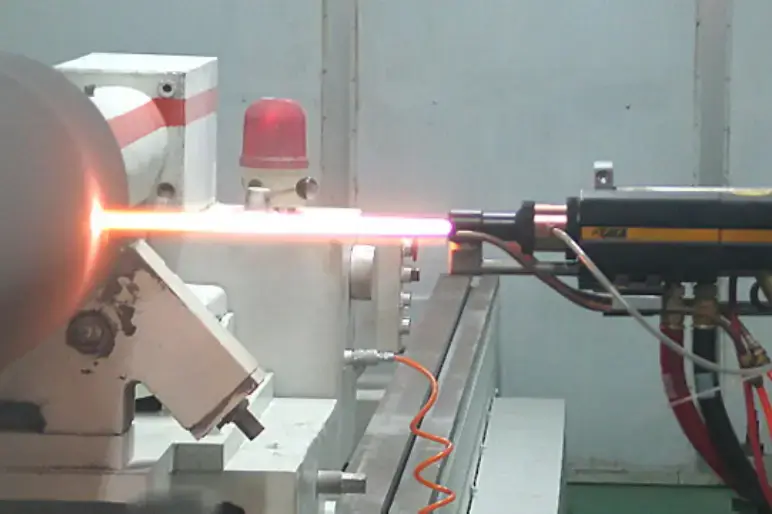

Flame Spray Gun

Price Range : ₹ 45K - 5Lakh

Air Transport

Sea Transport

Land Transport

- Rolls, pistons, and other equipment are protected against wear by flame spray gun coatings, which are widely employed in high wear sectors including mining and the steel industry.

- Oxygen and fuel gases are used in a Flame Spray gun to create a flame into which powder is shot. The coating is created by projecting the molten powder particles onto the work object.

- Many of the coatings sprayed using this method are subsequently heated at a temperature of about 1000°C in order to "fuse" them to the substrate surface.

4.5 Star Rating by our Precious Clients

- More Details

- Call Now

- Get Latest Price

![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

Flame spray gun price in India for sale. Flame spray gun process in which, the natural material in the form of a single wire, cord, or powder, is melted in an oxy-fuel gas flame. A cone of compressed air atomizes the molten material and propels it towards the workpiece.

These Plasma flame spray services are featured in our list of the most exclusive and highest quality services and goods (wire & powder). This service is extremely valuable in a variety of industrial, automotive, and mechanical applications because it provides exceptional coating capabilities while putting the least amount of heat into the base metal. Plasma flame spray services (wire, powder, and rod) have proven to be quite beneficial in corrosion control coatings (aluminium and zinc), Babbitt wire bearings, decorative coatings, EMI, and RFI shielding for defense, and other applications.

The advantage of the wire flame spray gun process is that the coatings are prepared for almost immediate use with no drying times and no risk of breaking the component. Flame spray systems can regularly manually run, semi-automated, or fully automated method if required.

Ambica Enterprises has applied its engineering superiority & vast knowledge of material technology to develop a complete line of flame spray guns for thermal spray gun applications. Guns that apply wear-resistant coatings on metallic, ceramic, carbide, and composite materials, as well as complete integrated flame spray gun systems for manual and automatic applications, are all part of our product offering. we have the best quality and low Flame Spray Gun price in India.

Specification of Flame Spray Gun

|

Air Pressure (psi) |

30 – 100 psi |

|

Nozzle Size (mm) |

0.3 mm |

|

Form |

Wire, Rod, Powder |

|

Item Weight (kg) |

15 |

|

Paint Color |

Blue, as per customer requirement |

|

Air Consumption |

8 to 9 cfm |

|

Air Inlet (NPT) |

3/8” |

|

Packaging Type |

Box |

|

Finish |

SA2.5 |

|

Sound pressure(dB) |

115 - 150 dB |

|

Material |

Mild Steel |

|

Minimum Order Quantity |

1 Number |

Type of Flame Spray Gun

Wire Flame Spray Gun

Wire or rod feedstock is used in the wire flame spray gun technique. The device included a nozzle in which fuel, most likely acetylene or hydrogen, was combined with oxygen and burned at the nozzle's tip. The molten metal was atomized and driven by a jet of compressed air encircling the flame. The process needed to be fed at a constant rate so that the wire melted and was propelled in a continuous stream.

Schoop solved the problem by driving the wire into the nozzle with a turbine that operated gears and drives rolls. Because he perceives this instrument to be comparable to a pistol or gun, he and we refer to thermal spray devices as "guns" or "pistols," not "torches." The thermal spray industry was founded on Schoop's concept of spraying solid metals, and it is frequently referred to as the Schoop Process. Regardless, the wire flame spray gun hasn't altered much since Schoop's time.

While the nozzle and air cap designs have changed, the core technique of pushing or pulling a wire into a flame, melting and atomizing it, and depositing the molten droplets to produce an adherent coating has remained the same.

Powder Flame Spray Gun

A thermal spray process in which the material to be sprayed is in powder form is known as a powder flame spray gun. Powder flame spray gun is the most straightforward of all the spray techniques to explain: feed a powder into the center bore of a nozzle, where it melts and is delivered to the work piece by exiting oxy-fuel fumes.

Unfortunately, this method produces coatings that are rich in oxides and have void contents of up to 20% volume percent (v/o). However, by delivering air to the nozzle through a tiny jet, the pressure in a chamber behind the nozzle can be reduced, improving coating quality.

Ceramic Rod Flame Spray Gun

A Ceramic Rod Flame Spray Gun process in which the material to be sprayed is in the shape of a ceramic rod. Plasma had not yet reached its full potential, and flame-sprayed powder coatings lacked the needed integrity and protection due to their porous nature. The Rokide cannon used "V" slotted fiber rolls to pinch the rods and feed them forward, whereas the wire gun used serrated steel rolls to grab and feed the wire.

The operating concept is the same in both guns: the nozzle's flame is concentric to the wire or rod to maximize uniform heating. The molten material is atomized and accelerated to the workpiece by a coaxial sheath of compressed gas around the flame. Both the wire and rod processes exhibit particle velocities of around 185 m/sec (600 ft/sec), with coating densities of around 95 v/o.

Features of Flame Spray Gun

- It is Reliable and efficient.

- Long-lasting material quality

- Its performance is high.

- Utilization is very easy.

Flame Spray Gun Price in India

Ambica Enterprises is a leading Manufacturer, Supplier & Exporter of the flame Spray gun, metalizing gun, thermal spray gun, wire arc spray gun, arc spray gun, zinc spray gun, thermal spray wire, sand blasting machine, shot blasting machine, grit blasting machine, sand Blasting cabinets, room, nozzles in India at a low price for sale.