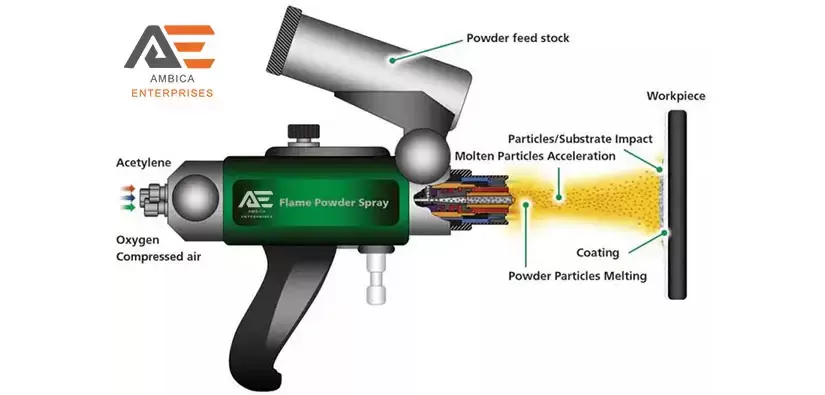

Working Behind Powder Flame Spray Gun

The Powder Flame Spray Gun process works a comparable technique as the Flame Wire Spray method, but that the wire flame spray gun feedstock is replaced by a powder. The main benefit of this method is that a much wider variety of materials (such as nickel or cobalt-based self Fixing composites or ceramic substances) can be easily treated into powder form providing a greater choice of coatings. Many compounds are difficult or cannot be presented in a wire form and for this purpose, it was produced.

Types of Flame Spray Gun

Flame spraying uses flame spray gun for coating. A thermal spray process variation in which the controlled explosion of a mixture of fuel gas, oxygen, and the powdered coating material is utilized to melt and propel the material to the workpiece. It includes low-velocity thermal spray powder, red, and wire flame processes and high-velocity processes.

Types of Thermal Spray Gun

A thermal spray gun is a spraying gun in which the molten liquid of abrasive is sprayed on the subject. This lays down a coating onto the surface of the subject. As the name suggests Thermal spray gun means a substance thermally sprayed on the subject.

Fundamentals of Twin Arc Spray Gun

Twin Wire Arc Spray Gun is a gun in which two wires anode and cathode respectively fed into the gun. When two wires touched it creates a spark and causes heating of those wires. Through which molten metal is poured onto the subject. The Twin Wire Arc gun process is a common commercial thermal spray process. It uses abrasive as a wire only other abrasive can't be used in Arc Spray Gun.

What are Blasting Cabinet and its types?

Blast Cabinet contains dust and abrasives. A machine is mounted for dust collecting which reduces air pressure inside the machine therefore which prevents dust from escaping into the environment. Shot blasting cabinet are built from very low carbon steel with an inner surface made of abrasive resistant materials including high strength alloy plates and rubber compounds. In the areas that are subject to direct high-velocity shot, alloy steel plates are used which have much more abrasive media resistance than others.

Mini Sand blasting Cabinet

Mini Sand blasting Cabinet is a cabinet consisting of many components use for sandblasting the substrate surface. Sand blasting is a process in which blasting abrasives is sand. it is a cabinet having all in one feature. We use this Mini Sand blasting Cabinet only for abrasives like 30/60 Mesh, Steel grit, Aluminum grit, Copper Slag, etc. Cabinet eliminates the requirement of safety equipment because the cabinet protects the operator from the microparticles of abrasive. There is no difference between the cabinet like Mini Grit Blasting Cabinet, Mini Sand Blasting Cabinet, Shot Blasting Cabinet.

The Portable Sand blasting Machine used to soften rough surfaces, this machine removes rust or corrosion from metal surfaces, gives a surface clean or shaped using abrasive media material known as media. There are many different types of sand blasting machines such as Portable Sand blaster, Automatic Sand Blaster, Blasting Cabinet, Tumblers, and many more.

A Portable Sand Blasting Machine used to soften rough surfaces, this machine removes rust from metal surfaces, gives a surface clean or shaped using abrasive material known as media. There are many different categories of Sand Blasting machines such as Portable Sandblaster, Automatic Sand Blaster, Blast Cabinet, Tumblers and many more. A Portable Sandblaster is often using by small and mid-sized companies such as Paint Shops, Auto Repair industry, Powder Coating Industry and many more.

Zinc Spray Booth

Zinc Spray Booth for LPG Cylinders are manufactured, supply and exporter by our company. Recently Shot blaster has manufactured a whole automatic zinc spray booth (aluminum spray booth) for one of the largest cylinder manufacturers in India, this system needs individual arbitration only for both types of cylinders and for the supervision of the method. The repeated condition can be verified with quantitative production. Cylinders to be connected vertically on an overhead conveyor which primarily goes to blasting cabinet and then to thermal spray coating booth. The Cylinder is placed manually on a twin roller conveyor which moves forward in the longitudinal direction as well as rotates inside the dry spray booth. The twin roller conveyor is driven by an electric motor.

Shot Blasting machines and Its equipment

The system that no metal industry owner can function without is shot Blasting. It is used in almost every industry that utilizes metal such as the aerospace industry, construction industry, automotive industry, foundry industry, rail industry, shipbuilding & many more. Shot Blasting Machine is utilized to clean, induce strength also known as shot peening / polishing the metal surfaces. The process of blasting has become an indispensable aspect of the metal building & the steel structure industry. This blasting system gives some major benefits for the protection & maintenance of steel & metal products. Before you get a look at the functioning of a shot blasting machine let us take a look at some of the advantages that make this procedure such an important part of the blasting industry.